On a recent five day Hinchinbrook trip I had a problem with my outboard that was readily solved thanks to the two crew members, Bruce Cordiner and Jason Hagen.

Early into a trip to Zoe Bay the overheat alarm went on my aging outboard. An inspection under the cowling revealed a corrosion hole had appeared in the top of the thermostat housing on the motor.

Luckily both Bruce and Jason had a stick of Evercoat Aluminox Epoxy Stick, which is a product designed to repair aluminium, even under water. Talk about pulling a rabbit from the hat! John Wedrat had also brought a set of small files in Cardwell prior to departing on the houseboat. While the small files weren’t absolutely necessity, as I had a large flat file, but they made the job of cleaning the alloy thermostat housing back to bare metal a lot easier.

Once an area of about 6cm2 was filed back to bare alloy, and the hole filed back to bare metal, it was time to mix the epoxy and set it in place. I had attempted to remove the thermostat so I could press the resin from the inside of the housing as well as from on top. I couldn’t get the thermostat out easily, so I left it alone, as my mechanic had informed me that this particular outboard needed the thermostat in place for the computer to operate properly.

I pressed the resin down firmly over the whole cleaned surface, leaving it about 4mm thick over the hole. The epoxy was left to set with the help of direct sunlight and a sample piece was kept on hand to test how it was hardening. To be sure, I left it about eight hours to cure before starting the motor. Hey presto! No leak, so the cowling was replaced and we went fishing.

We only got about 200m when the overheat alarm went again and I noticed the telltale wasn’t working, though it was when we first set out. Obviously some particles had been dislodged when filing the hole in the thermostat housing. They were soon removed with the use of a thin piece of cooper wire about 30cm long, which I always carry for clearing sand out of the telltale when crabbing in shallow water.

Off we set again, but almost immediately the alarm went off, so it was time to remove the thermostat. To my great relief it came out in one piece. I found that a piece of the epoxy resin had protruded into the internal workings of the thermostat when I was pressing it in place and I think this was preventing the thermostat from fully opening. Once the housing was put back together, minus the thermostat, all the problems had been fixed and we fished for another two days without incident.

Once we returned to Cairns I began thinking about a more permanent solution to the problem and sought advice from a few people in the know. After the first crabbing trip I noticed a few drops of water starting to come from under the patch, so a more permanent solution had to be found. I spoke to staff at Norweld, one of the major alloy welding businesses in Cairns, and they felt it could be welded, so I took the boat in for a closer inspection. One of their very experienced welders checked it out and felt sure he could weld up the hole.

$33 later I had a long-term solution to the problem. I have used the motor on a number of occasions since without incident. I have left the thermostat out and the outboard has been running perfectly.

As you can imagine, top of my shopping list when I got back from Hinchinbrook was an Evercoat Aluminox Epoxy Stick.

Reads: 1903

The hole in the top of the thermostat housing once the loose flakes of corrosion had been picked off, and before filing. The thermostat casing had been taken off but the thermostat wouldn’t come out.

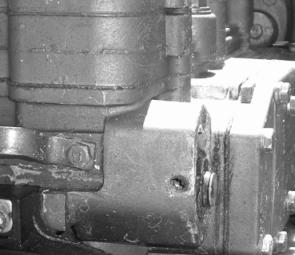

The hole and surface after being filed back to bare alloy.

The hole was welded over at Norweld.

The final solution – I used some paint to cover the repair.

John Wedrat’s set of small files made the initial repair a lot easier.

After the thermostat casing had been replaced.